Coining technology

Brief technological history of coinage.

Broadly speaking, the coin has been hammered since its invention around 640 BC until even beyond the 16th century. In 1551, German technicians invented a process by which metal was flattened and drawn in a hydraulic rolling mill with two parallel rollers, and then stamped on the metal using the same process. Hydraulic mills were introduced in Segovia in 1585, having previously been established in 13 other mints in Germany, England, France, Austria, Slovakia, Romania, Switzerland and Poland. At the end of the 16th century, other types of presses were invented, such as the Taschenwerk (rocker press) which was used in small mints throughout Europe. The flywheel press, drawn by Leonardo da Vinci, began to spread around the middle of the 17th century and was installed in Madrid, Seville, around 1700, in the Indian Mints between 1732 and 1769, and in Segovia in 1772. Sometimes two or even three different techniques were used simultaneously in some mints. All the mints in the world that survived the centralisation of governments adopted automatic minting presses from the mid-19th century, and today there are models that can mint up to 800 coins per minute.

The industrial processes used in the mass production of currency - under strict regulations and for the state - have always been one of the most complex and exact in the history of industry until the beginning of the Industrial Revolution during the second half of the 18th century. The Royal Mill Mint (1583) was the 14th mint to be mechanised when this conversion began in 1551. The fact that it is the largest, most advanced and most complete mint still standing indicates that the Segovia plant is the first testimony of a modern industrial plant. You can read about this thesis in the book by Dr. Glenn Murray, recently presented by the Chamber of Commerce of Segovia, with the title "The Royal Mill Mint, the oldest, most advanced and complete industrial factory still standing - World Heritage".

Description of the industrial processes for coining.

WEIGHING

Weighing of the metal being coined has been done since minting began in 640 B.C. There many different types and sizes of scales.

ASSAY

The assayer controls the fineness of all metal being processed, by assaying samples in his small oven. His symbol appears on each coin as a guarantee.

FOUNDRY

Melting of the metal takes place in giant crucibles over blazing charcoal. The liquid alloy is then poured into molds to form small ingots.

SCRAPS AND SWEEPINGS

Scrap, clippings, filings, defective coins and sweepings from all departments are carefully controlled by weight, for recycling in a future melt.

METAL ROLLING

Since ancient times, mints used hammers to pound out sheets of metal. In 1551 Germans invented a rolling mill for flattening and stretching metal.

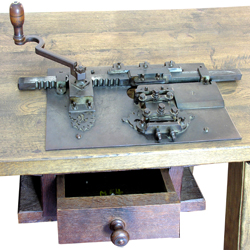

DRAW BENCH

The draw bench was introduced into Spanish mints at the same time as screw presses starting in 1728. The machine is used to stretch and flatten metal.

ANNEALING

Metal hardens as it is being worked. To restore ductility, metal is annealed, or heated glowing red in a special oven and then allowed to cool slowly.

BLANCHING

Metal blackens in the annealing process. Before the final striking, the metal is blanched in a bath of hot acid and dried, so the new coin will shine.

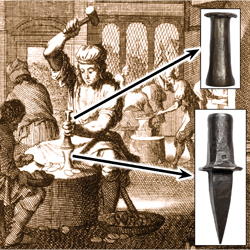

HAMMER COINING

System invented in 640 B.C. to produce earliest coinage. Ubiquitous in mints worldwide, this technique endured until 1773 in Spanish coinage.

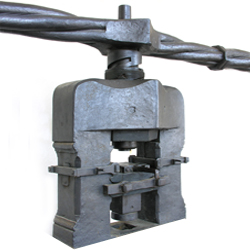

ROLLER MILL COINING

Coining with roller dies was invented in Germany in 1551. Introduced in Segovia in 1585, this system was used by some mints in Europe until 1770.

ROCKER PRESS COINING

The rocker press was invented in Germany and uses curved dies. It was used at many European mints from 1598 to 1790, as shown by dies known today.

SCREW PRESS COINING

Screw press coining avoids the defects caused when minting with curved dies. This press becomes popular in mints worldwide between 1650 and 1850.

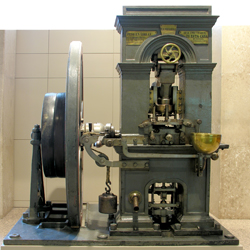

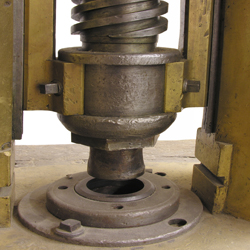

AUTOMATIC COINING PRESSES

Installed with steam engines in mints worldwide starting around 1850, these machines have automatic blank feeders which allow for very rapid coining.

COINING IN MOLDS

In rare instances, molds have been used to produce coins. The main disadvantage to this method is that it produces coins very easy to counterfeit.

OTHER TYPES OF COINING PRESSES

During the 18th and 19th centuries other types of machines were invented to either strike coins or cut blanks from strips, such as the drop press.

BLANKING OR CUTTING

Since antiquity, blanks were cut with sheers, from strips of metal previously flattened by hammer, then rounded. The blanking machine dates from 1551.

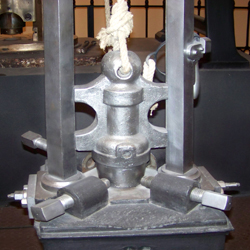

EDGE MILLING

The edge milling machine was invented in 1679 and installed at the Paris Mint in 1686. In 1707 the French inventor introduces his machine in Spain.

ENGRAVING OFFICE

One of the most important departments of a mint. It requires an achieved specialist not only in engraving but also in metallurgy, to harden the dies.

SMITHY

Specialized department for producing cylindrical rollers used in the laminating mills. Contains forge, bellows, giant drop hammer, and metal lathe.

VARIOUS MISC.

In this category we include images that don't coincide with the above listing, but that we feel are of interest.